Hybrid Technology on Ceramic Substrates

by Sara Caron

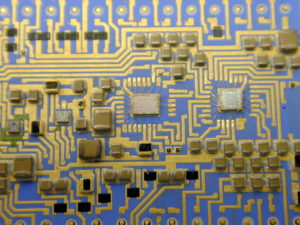

MPT Senior Engineer

MPT makes a variety of hybrids, from audio and power circuits to high frequency hybrids. We offer circuits from high frequency couplers with little active components to audio preamplifiers with many active die components. Examples are found on various pages of this web site. We also support high frequency circuits (1-10 GHz) with chip and wire. Some hybrids offer surface mount components as well as printed thick film resistors. Some of the applications include opto-electronic circuitry where precise placement of the opto-diode die is critical and placement was achieved.

Typically alumina is used as the carrier unless greater thermal conductivity is required. The volume and surface resistivity make it ideal as a carrier as well as its high fracture strength. However, its low coefficient of thermal expansion must be traded off when installed in a housing which is made of metal such as aluminum. Generally speaking, epoxy or an epoxy preform is used as an intermediate layer providing the interface (mechanical and possibly electrical) needed for attachment to the housing.

Circuit layers, like a printed wiring board, are screened on the carrier with layers of ceramic dielectric paste to isolate traces. Bondable conductor pads are on top and cleared of dielectric material. MPT guidelines are contained here. Resistors may be printed on the dielectric layers to reduce size, narrow tolerance, improve temperature coefficient, and improve breakdown voltage over traditional SMT resistors. Traces down to 5 mils wide with spacings of 5 mils between traces are standard. Typical conductor thickness of traces are 10-12 micron thick. General layout guidelines for designing a hybrid circuit with thick film technology are contained here. A forthcoming blog post will detail the various construction options of the technology.

MPT uses both conductive and non-conductive epoxy and preforms. Conductive epoxy/preforms are used when the case and the ground layer of circuit is electrically uniform as with high frequency circuits. Low-frequency or dc circuits generally don’t have a ground layer and may use non-conductive epoxy. Ground, then, is connected to the case via wirebonds.

MPT offers hybrid assembly services as well. Details can also be found on our web pages. We also offer reverse engineering plus size reduction for various circuits.

For further information, please contact:

Micro-Precision Technologies, Inc.

10 Manor Parkway, Suite C

Salem, NH 03079

603-893-7600

www.micropt.com

[email protected]

Certifications

MPT is MIL-PRF-38534 Class H qualified since 1998, QML-38534 listed, certified by DSCC (Defense Supply Center, Columbus, OH). MPT is AS9100D ISO 9001:2015, and ITAR registered.