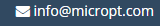

MPT Services

MPT is proud to offer the following assembly services.

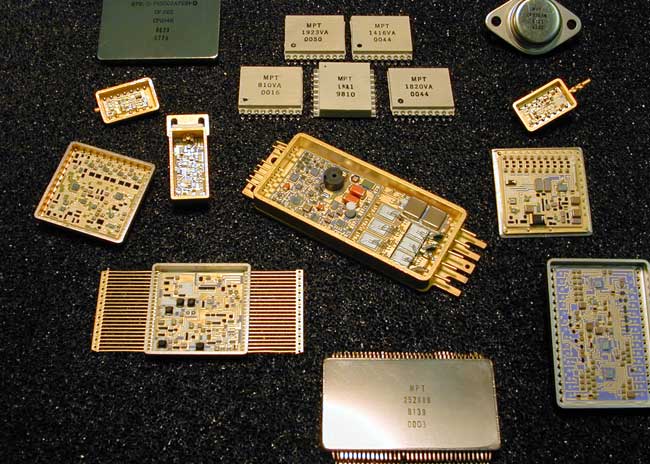

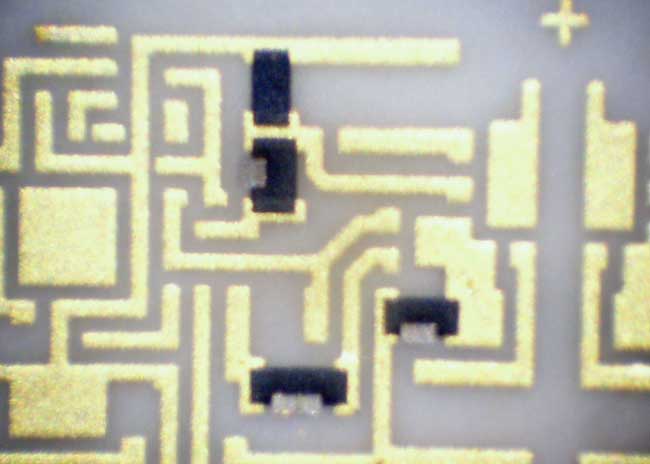

Hybrid Microcircuit Assembly: Hybrid assembly consists of attaching components onto a screened substrate and sealing the substrate into a package. MPT provides quick turn-around for prototypes and in-time production and has clean areas of Class 100 for pre-cap inspection and class 10,000 for assembly.

Semiconductor Packaging: We can repackage a standard or customized die into a different package which may improve the thermal performance, pinout configuration, electrical performance, or mechanical size and shape according to the customer’s specific application requirements.

Obsolete Semiconductors: For customers that require a technical solution to their obsolescence problem, at MPT we can design a cost-effective solution to create a pin to pin compatible replacement, guaranteed to meet the form, fit and functional specifications of the original part.

Reverse Engineering: MPT specializes in reverse engineering of legacy and other components. MPT can generate a schematic from the part itself by deconstructing the part and building a data package: blueprints, schematics, bill of materials. This data package allows MPT to reconstruct the component and replicate the part as necessary.

Design & Layout: MPT can take your circuit from design to completed component. Our process is tested and highly reliable, with fast turnaround.

Wire Bonding & Die Attachment: MPT has both manual and automated wire-bonding and die-attach capabilities. These include ball and wedge bonding, auto die attach and auto dispense for epoxy, encapsulate or optical fluid.

Download Documents (PDFs)

Capabilities Brochure

Talk To Our Engineers

- P: 603-893-7600

- Below is our Quick Contact form. To send us a file, use our Quote form instead.

Certifications

MPT is MIL-PRF-38534 Class H qualified since 1998, QML-38534 listed, certified by DSCC (Defense Supply Center, Columbus, OH). MPT is AS9100D ISO 9001:2015, and ITAR registered.