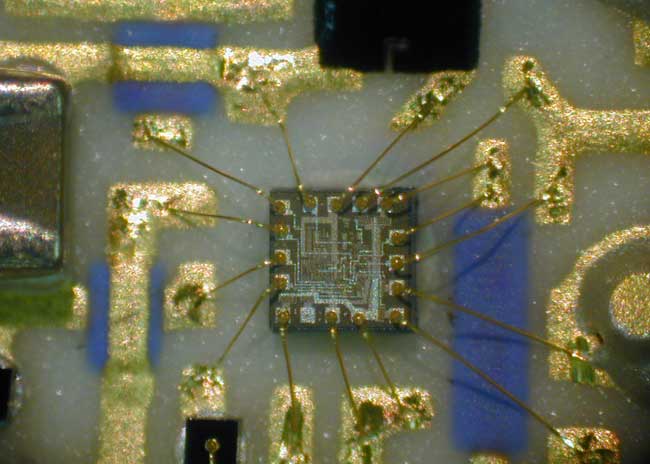

Wire Bonding

Connecting one conductive surface to another conductive surface via fine gold or aluminum wires.

MIL-STD-883 standards define MPT wire bonding processes. MPT’s expertise makes our wire bonding processes flexible and small-lot friendly. Call to talk to an engineer about your wire bond, die attach or hybrid assembly needs.

Wire Bonding Methods

Ball Bond

Ball bonding uses round gold wire (typically 0.001” in diameter). An electric discharge creates a ball at one end of the wire which is bonded to a conductive surface with a thermosonic ball bond on a heated stage. The second bond is a wedge bond, which can be topped with a security ball bond. Ball bonds are able to bond to a smaller bond pad than wedge bonds. Click here for more information on equipment.

Wedge Bond

Wedge bonding can use either gold or aluminum wire or ribbon and is created by ultrasonically welding the wire between a rectangular wedge tool and the bond pad. An oval shaped bond results, which is very strong and is well suited for larger wires and higher power. Gold wire bonding requires a heated stage, while Aluminum wedge bonding occurs at room temperature, which can avoid thermal damage to some sensitive components. Most IC’s include Aluminum metalized bond pads, so Aluminum wire bonds also avoid any intermetallic formation between gold and aluminum which can lead to reliability issues over time particularly at higher temperatures.

Die Attachment

Attachment of a die to the surface of a circuit. Typically attached with epoxy and wire-bonded.

MPT expertise makes our die attachment processes flexible and small-lot friendly. All processes comply to MIL-STD-883. Call to talk to an engineer about your hybrid assembly.

Equipment

Wire bond and die attach equipment include Westbond Auto ball/wedge bonder, Hughes 2460-V Auto wedge bonder, Hesse Mechatronics BJ820 wedge bonder with heated stage for high speed wedge bonding of Gold or Aluminum wires, 2-MRSI 505 die attach system, MRSI 170 Dispense system, and a variety of manual equipment to meet the needs of nearly any microelectronics assembly application. Click here for more information on equipment.

Why Micro-Precision Technologies

- Small Lot Friendly

- New Product Introduction (NPI)

- Consigned or Full Turnkey Assemblies

- Class 10,000 Cleanroom for Assembly (0.5 micron per cubic foot)

- Class 100 Cleanroom for Pre-Cap Inspection (0.5 micron per cubic foot)

- AS9100D ISO-9001:2015 Certified

- MIL-PRF-38534 Class H Qualified

- QML-38534 Listed

Download Documents (PDFs)

Capabilities Brochure

Talk To Our Engineers

- P: 603-893-7600

- E: [email protected]

- Below is our Quick Contact form. To send us a file, use our Quote form instead.

Certifications

MPT is MIL-PRF-38534 Class H qualified since 1998, QML-38534 listed, certified by DSCC (Defense Supply Center, Columbus, OH). MPT is AS9100D ISO 9001:2015, and ITAR registered.